MARCOVIS FM-X3/PA +Vis TF/Zn

- Through dowel /polyamide + countersunk screw /zinc plated, not mounted, for solid and hollow materials.

Applications

- Anchor for non-structural applications in indoor environments.

- Increased expansion designed for facade and heavy carpentry.

Advantages

- Universal extra-flexible high-quality nylon anchor for solid and hollow materials. Delivered complete: non-assembled anchor + screw.

- Maximum tensile strength up to 2000 kg, exceptional performance on all types of materials, solid and hollow.

- Up to 3 installation depths: Ensures versatility of use and a unique fit for multiple applications. Reduced installation depth allows maximum savings in drilling and installation time.

- Dynamic tip: The closed end and conical shape facilitate insertion into the hole. During expansion, this special geometry generates a strong additional expansion which further increases the extraction resistance.

- Increased expansion: The screw and plug work together to create an innovative variable geometry expansion that works even in hollow support materials or irregular holes.

- Fins along the peg ensure proper installation without peg rotation.

- The fins under the head guarantee the adhesion of the plug with the element to be fixed.

- The large flange for fastening metal structures prevents corrosion caused by contact between the bracket and screw.

Technical characteristics

| With flange |

True |

| Installation mode |

Hammer laying Inslallation with cruciform screwdriving Installation with torx screwdriving Installation with hexagonal screwdriving |

| Supporting material |

Cellular concrete Concrete Hollow brick Solid brick Hollow concrete block Solid concrete block Natural stone with prior testing |

| Product material |

PA6 polyamide + Zinc-plated steel |

| Head shape |

Coutersunked head |

| Maximum thickness of the element to be fixed |

10 10/-/- 110/90/70 150/130/110 180/160/140 20/10/- 210/190/170 240/220/200 25 30/10/- 35 40/30/- 45 50/30/10 60/50/- 70/50/30 80/70/- 90/70/50 |

| Minimum drilling depth |

40 Hnom+15 |

| Minimum depth of implementation |

25 40/50/- 50/-/- 50/70/- 50/70/90 |

| Content |

100 dowels Ø6/20-25x50 polyamide +100 zinc-plated Pozidriv2 countersunk screws, not mounted. 100 dowels Ø6/30-35x60 polyamide + 100 zinc-plated Pozidriv2 countersunk screws not mounted. 100 dowels Ø6/40-45x70 polyamide +100 zinc-plated Pozidriv2 countersunk screws not mounted. 100 dowels Ø6/5-10x35 polyamide +100 zinc-plated countersunk Pozidriv2 screws not mounted. 50 dowels Ø10/10-30x80 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/10x200 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/10x230 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/10x60 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/170-210x260 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/200-240x290 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/30-50x100 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/50-70x120 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/70-90x140 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø10/90-110x160 polyamide +50 zinc-plated countersunk Torx40 screws with standard flange not mounted. 50 dowels Ø8/10-20x60 polyamide +50 zinc-plated countersunk Torx30 screws with standard flange not mounted. 50 dowels Ø8/30-40x80 polyamide +50 zinc-plated countersunk Torx30 screws with standard flange not mounted. 50 dowels Ø8/50-60x100 polyamide +50 zinc-plated countersunk Torx30 screws with standard flange not mounted. 50 dowels Ø8/70-80x120 polyamide +50 zinc-plated countersunk Torx30 screws with standard flange not mounted. |

| Type of load |

Light load |

| Minimum thickness of base material |

100 100/-/- 100/100/- 100/120/- 100/120/240 |

| Generic code | d0

(mm)

Support drilling diameter

|

L

(mm)

Length

|

H1

Minimum drilling depth

|

Hnom

Minimum depth of implementation

|

|

| 352040MARCOVIS FM-X3 TF/TX30/ZN 10-20/8X60 | 8 | 60 | Hnom+15 | 40/50/- | |

| 352042MARCOVIS FM-X3 TF/TX30/ZN 30-40/8X80 | 8 | 80 | Hnom+15 | 40/50/- | |

| 352044MARCOVIS FM-X3 TF/TX30/ZN 50-60/8X100 | 8 | 100 | Hnom+15 | 40/50/- | |

| 352046MARCOVIS FM-X3 TF/TX30/ZN 70-80/8X120 | 8 | 120 | Hnom+15 | 40/50/- | |

| 352048MARCOVIS FM-X3 TF/TX40/ZN 10/10X60 | 10 | 60 | Hnom+15 | 50/-/- | |

| 352050MARCOVIS FM-X3 TF/TX40/ZN 10-30/10X80 | 10 | 80 | Hnom+15 | 50/70/- | |

| 352052MARCOVIS FM-X3 TF/TX40/ZN 30-50/10X100 | 10 | 100 | Hnom+15 | 50/70/90 | |

| 352054MARCOVIS FM-X3 TF/TX40/ZN 50-70/10X120 | 10 | 120 | Hnom+15 | 50/70/90 | |

| 352056MARCOVIS FM-X3 TF/TX40/ZN 70-90/10X140 | 10 | 140 | Hnom+15 | 50/70/90 | |

| 352057MARCOVIS FM-X3 TF/Tx40/ZN 170-210/10x200 | 10 | 200 | Hnom+15 | 50/70/90 | |

| 352058MARCOVIS FM-X3 TF/TX40/ZN 90-110/10X160 | 10 | 160 | Hnom+15 | 50/70/90 | |

| 352059MARCOVIS FM-X3 TF/TX40/ZN 170-210/10X260 | 10 | 260 | Hnom+15 | 50/70/90 | |

| 352061MARCOVIS FM-X3 TF/TX40/ZN 200-200/10X290 | 10 | 290 | Hnom+15 | 50/70/90 | |

| 352065MARCOVIS FM-X3 TF/Tx40/ZN 200-200/10x230 | 10 | 230 | Hnom+15 | 50/70/90 |

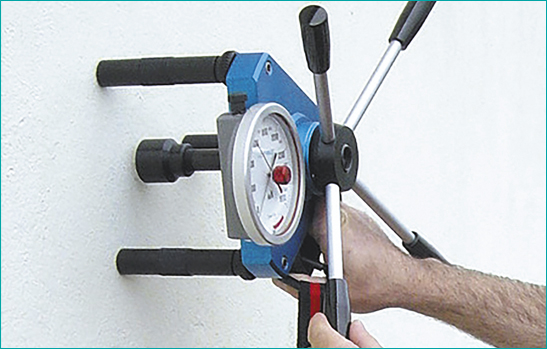

Pull Out test

ETANCO carries out pull-out tests on site to validate the best solution. Following the tests, a report will be provided to you to justify the maximum resistance value of the anchoring in the support material of your site.

Discover

Integrated engineering office

We place our customers at the heart of our priorities to ensure that we listen to them and advise them on a daily basis. Since each application requires different fixing solutions, our design offices are on hand to guide you in your choices. ETANCO will draw up a personalised and adapted calculation note free of charge (according to the regulations in force and the reference documents for each fastener).

Discover

Software Specif Chevilles

Simple, effective and fast, SPECIF determines and calculates the right anchor for your site. Your customised anchor solution.

Discover- In accordance with the ETA 19 0245 anchors FM-X3

-

Commercial video

-

Commercial video