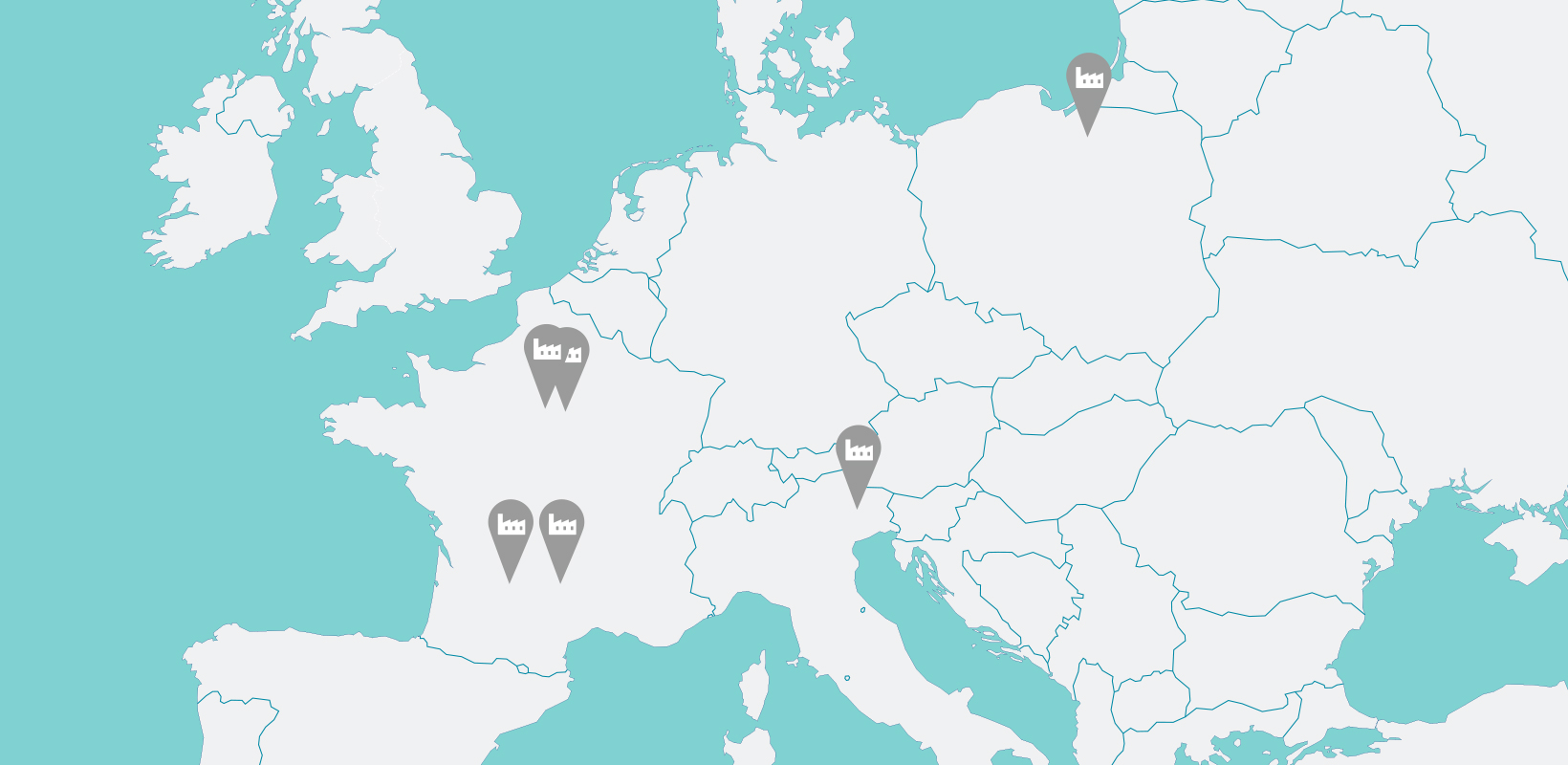

Sites de production

Le groupe ETANCO possède 6 sites de production présents en Europe.

A chaque site, son expertise et ses technologies.

- Laquage des vis & accessoires

- Plusieurs chaines de laquage

- + de 2000 couleurs (dont 20 RAL standards)

- Des coloris sur mesure en grandes ou petites séries En savoir plus sur le laquage

- Métallerie

- Une technologie de surmoulage Zamak par injection, unique en Europe.

- Plus de 60 millions de vis produites avec une tête surmoulée en Zamak

- Des presses à injection plastique de 40 à 400 tonnes

- L’utilisation de plus de 300 tonnes de matière plastique : polyamide, polypropylène, PEHD.

- L’utilisation de plus de 3500 tonnes de feuillard d’acier par an en découpe

- 1400 tonnes de pièces en galvanisation

- 300 tonnes en sherardisation

- En savoir plus sur LRD

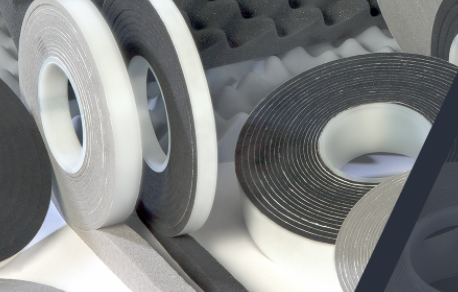

- Que cela soit la découpe, l’adhésivage, le collage, la soudure, etc., Plastiform’s exploite tous les procédés

- Et sur l’ensemble des mousses techniques : Polyéthylène, EPDM, Polyuréthanes souples ou élastomères de polyuréthane

- En savoir plus sur Plastiform’s

- Formage à froid

- Découpe et estampage du métal,

- Injection plastique

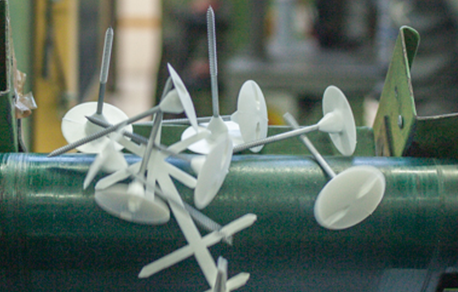

Le site industriel ETANCO d’Aubergenville en France, s’étendant sur 35 000 m², dont 8 000 m² pour la production avec une équipe de 75 personnes.

Etanco y fabrique, par exemple, des vis autoperçeuses laquées en acier ou bi-métal (Colorvis, Drillnox, Colorstop,...) et des cavaliers pour couverture.(Vulco,...).

Le site industriel LRMI d’Aubergenville en France est spécialisé en surmoulage zamak et injection plastique. Le site assoie son expertise sur :

LRMI, y fabrique, par exemple, des systèmes à rupture de pont thermique pour fixation d’étanchéité (Etancoplast,...) et des vis autoperçeuses avec tête surmoulée Zamak (Zacrovis).

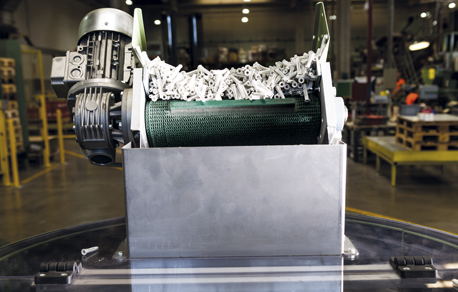

Etabli sur 2 sites en Haute vienne : Saint Germain-Les-Belles d’une part et Magnac-Bourg d’autre part, LRD est spécialiste depuis plus de 30 ans de la découpe et de l’emboutissage de pièces métalliques. LRD utilise également des procédés de galvanisation à chaud et de shérardisation (procédé complémentaire à la galvanisation à chaud qui permet d’appliquer du zinc par thermodiffusion sur les pièces métalliques).

LRD fabrique des cavaliers pour la fixation de bac (Cavaliers Vulco) des plaquettes de répartition et des équerres de façade (Isolco,..)

La société Plastiform’s existe depuis 1964 et transforme les matériaux cellulaires appelés plus souvent mousses ou mousses cellulaires. Depuis de nombreuses années, la société a axé ses développements vers les marchés techniques nécessitant des moyens spécifiques et des savoir-faire particuliers. Située idéalement sur un carrefour autoroutier entre un axe Nord/Sud et un axe Est/Ouest, Plastiform’s peut servir facilement tous les marchés de l’Hexagone ainsi que l’export vers l’Europe occidentale.

FRIULSIDER confirme son rôle de référence internationale de premier plan dans les fixations sures (chevilles & vis) en s’appuyant sur une expérience de plus de 50 ans & diverses technologies :

Friulsider fabrique, par exemple, des chevilles, des vis à bois, des vis bi-métal,...

En 2017, le groupe ETANCO a finalisé l’acquisition de la société Gunnebo fastening Pologne, basée à Orneta.

Avec une usine de plus de 15 000 m², nous renforçons notre dispositif industriel et augmentons nos capacités de production dans les domaines du traitement de surface, de l’injection plastique, du laquage et du conditionnement, pour mieux répondre aux besoins de nos marchés, notamment en Europe de l’Est .

Etanco Pologne fabrique, par exemple, des vis autoperçeuses laquées (Colorvis, Ecovis),...