ATS EVO-SC TF /Zn

- Safety dowel with pre-assembled / zinc-plated H hollow countersunk screw, for cracked and non-cracked concrete.

Applications

- Intended use: cracked and non-cracked concrete - Applications for heavy loads.

Advantages

- Safety of installation: self-expanding dowel.

- High resistance to shear loads.

- Delivered complete: dowel + threaded rod + washer + nut assembled.

- Seismic approval C1 and C2 (TR045).

Technical characteristics

| Type of load |

Heavy load |

| Load recovery |

6 428 Kg |

| Installation mode |

Hammer laying |

| Supporting material |

Cracked concrete Concrete |

| Minimum drilling depth |

115 75 85 95 |

| Product material |

Zinc plated steel |

| Minimum depth of implementation |

100 60 70 80 |

| Pre-assembled product |

True |

| Minimum thickness of base material |

100 118 134 176 |

| Effective anchoring depth |

49 59 67 88 |

| Maximum thickness of the element to be fixed |

15 16 17 25 26 27 33 |

| Content |

20 dowels M10/27x100 zinc-plated +20 pre-assembled zinc-plated countersunk head screw H hollow8. 20 dowels M12/33x125 zinc-plated +20 preassembled H hollow10 countersunk screws zinc-plated. 20 zinc-plated dowels M10/17x90 +20 pre-assembled zinc-plated countersunk screw H hollow8. 25 dowels M8/16x80 zinc-plated +25 pre-assembled countersunk screw H hollow6 zinc-plated. 25 dowels M8/26x90 zinc-plated +25 pre-assembled countersunk screw H hollow6 zinc-plated. 50 dowels M6/15x70 zinc-plated +50 pre-assembled H hollow5 countersunk screws zinc-plated. 50 dowels M6/25x80 zinc-plated +50 preassembled zinc-plated countersunk head screws H hollow5. |

| Internal diameter |

M10 M12 M6 M8 |

| Generic code | L

(mm)

Length

|

d0

(mm)

Support drilling diameter

|

Hnom

Minimum depth of implementation

|

Hmin

Minimum thickness of base material

|

Hef

Effective anchoring depth

|

|

| 344546ATS-SC EVO M10/17x90 (20p) | 90 | 15 | 80 | 134 | 67 | |

| 344547ATS-SC EVO M10/27x100 (20p) | 100 | 15 | 80 | 134 | 67 | |

| 344548ATS-SC EVO M12/33x125 (20p) | 125 | 18 | 100 | 176 | 88 |

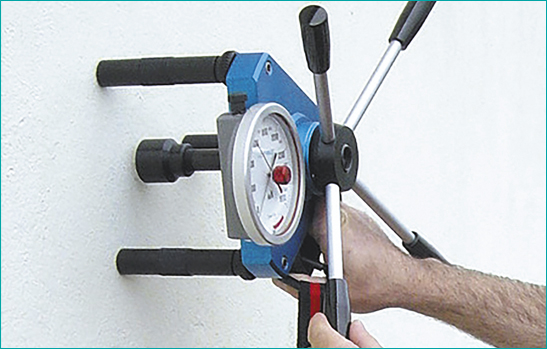

Pull Out test

ETANCO carries out pull-out tests on site to validate the best solution. Following the tests, a report will be provided to you to justify the maximum resistance value of the anchoring in the support material of your site.

Discover

Integrated engineering office

We place our customers at the heart of our priorities to ensure that we listen to them and advise them on a daily basis. Since each application requires different fixing solutions, our design offices are on hand to guide you in your choices. ETANCO will draw up a personalised and adapted calculation note free of charge (according to the regulations in force and the reference documents for each fastener).

Discover

Software Specif Chevilles

Simple, effective and fast, SPECIF determines and calculates the right anchor for your site. Your customised anchor solution.

Discover- In accordance with the ETA 10 0423 anchors ATS EVO ZN

Find our technical sheets and declarations of performance in the generic code product page.

-

Commercial video