TAPCO TF /PA +Clou /InA2

- Cheville-clou à frapper /polyamide à collerette fraisée + clou /inox A2 à tête fraisée pozidriv prémonté.

Applications

- Usage prévu : Matériaux pleins béton fissuré et non fissuré C20/25 - Matériaux creux avec essais préalables - Applications risques élevés.

- Fixation de vêture, de vêtage et accessoires sur : matériaux pleins - béton fissuré - non fissuré - matériaux creux.

Avantages

- Cheville-clou prémontée à frapper.

- Pose rapide pour fixation en série.

- Montage au travers.

- Démontage possible au tournevis empreinte Pozidriv.

- Grandes longueurs, épaisseurs à fixer importantes.

- Livrée complète : cheville + clou montés.

Caractéristiques techniques

| Avec Collerette |

Vrai |

| Mode de pose |

Pose au marteau Pose par Vissage Cruciform |

| Type empreintes |

Pozidriv(Pz) |

| Matériau support |

Béton fissuré Brique pleine Parpaing plein Parpaing creux avec essais préalables Béton cellulaire avec essais préalables Pierre naturelle avec essais préalables Brique creuse avec essais préalables |

| Matière du produit |

Polyamide PA6 + Acier inox A2 |

| Produit prémonté |

Vrai |

| Type d'empreintes Pozidriv |

Pozidriv (Pz) 2 |

| Forme de têtes |

Tête fraisée (TF) |

| Epaisseur maxi de l'élément à fixer |

10 15 20 5 |

| Profondeur Perçage mini |

35 40 |

| Profondeur min de mise en œuvre |

25 30 |

| Contenu |

100 chevilles-clous Ø6/20x50 polyamide à collerette fraisée + 100 clous inox A2 tête fraisée Pozidriv2 prémontés. 200 chevilles-clous Ø5/15x40 polyamide à collerette fraisée + 200 clous inox A2 tête fraisée Pozidriv2 prémontés. 200 chevilles-clous Ø6/10x40 polyamide à collerette fraisée + 200 clous inox A2 tête fraisée Pozidriv2 prémontés. 300 chevilles-clous Ø5/5x30 polyamide à collerette fraisée + 300 clous inox A2 tête fraisée Pozidriv2 prémontés. |

| Reprise de charge |

154 Kg |

| Type de charge |

Charge légère |

| Epaisseur mini du matériau support |

50 60 |

| Code générique | d0

(mm)

Diamètre de perçage du support

|

L

(mm)

Longueur

|

H1

Profondeur Perçage mini

|

Hnom

Profondeur min de mise en œuvre

|

|

| 359990TAPCO TF 5/5x30 InA2 | 5 | 30 | 35 | 25 | |

| 359991TAPCO TF 5/15x40 InA2 | 5 | 40 | 35 | 25 | |

| 359995TAPCO TF 6/10x40 InA2 | 6 | 40 | 40 | 30 | |

| 359996TAPCO TF 6/20X50 InA2 | 6 | 50 | 40 | 30 |

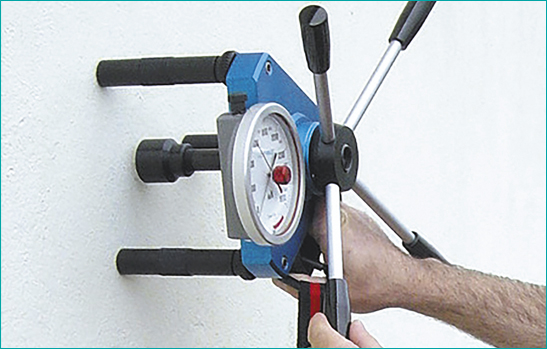

Essai d'arrachement

ETANCO réalise des essais d'arrachement sur site pour valider la meilleure solution. Suite aux essais, un rapport vous sera fourni afin de justifier la valeur de résistance maximum de l'ancrage dans le matériau support de votre chantier.

Découvrir

Bureau d'étude intégré

Nous plaçons notre client au coeur de nos priorités pour lui assurer une écoute et un conseil au quotidien. Puisque chaque application exige des solutions de fixations différentes, nos bureaux d’études sont présents pour vous guider dans vos choix. ETANCO réalise gratuitement la rédaction d’une note de calcul personnalisée et adaptée (selon la réglementation en vigueur et d’après les documents de référence de chaque fixation).

Découvrir

Logiciel Specif chevilles

Simple, performant et rapide, SPECIF détermine et calcule la bonne cheville en adéquation avec votre chantier. Votre solution cheville sur mesure.

Découvrir- En conformité avec l' ETE 10 0190 chevilles TAPCO TAP-LARGE Sauf codes articles (359990, 359991 )

Retrouvez nos fiches techniques et déclarations de performance dans les fiches produits codes génériques.

-

Vidéo commerciale